SanDisk Sansa Clip MP3 Player: A Comprehensive Instruction Manual Guide

Welcome! This guide provides detailed instructions for your SanDisk Sansa Clip‚ a budget-friendly‚ feature-rich MP3 player‚ offering a superb audio experience.

The SanDisk Sansa Clip represents a compelling entry point into the world of portable digital music. Standing out in a market dominated by larger players‚ the Clip distinguishes itself through its remarkably small size‚ lightweight design‚ and surprisingly robust feature set‚ all offered at an exceptionally affordable price point. This makes it an ideal choice for users seeking a dedicated music player without the complexities – or the cost – of smartphones or larger dedicated devices.

Initially released to compete with offerings like Apple’s Shuffle and Creative’s Zen Stone‚ the Sansa Clip quickly gained traction due to its ease of use and practical functionality. SanDisk strategically focused on delivering core features effectively‚ including ample storage (with models expanding to 8GB)‚ a clear OLED display‚ and a convenient built-in belt clip for effortless portability. The device’s success is also rooted in its compatibility with various audio formats and its ability to be easily managed through software like Windows Media Player and‚ with the aid of the SanDisk Media Converter‚ iTunes.

Unboxing and Initial Setup

Your SanDisk Sansa Clip package should contain the MP3 player itself‚ a small quick-start guide‚ and a USB cable for data transfer and charging. Carefully remove all components from the packaging‚ inspecting for any visible damage. Before first use‚ it’s crucial to fully charge the device. Connect the Sansa Clip to your computer using the provided USB cable.

The player should appear as a removable drive on your computer. No drivers are typically required for Windows or macOS. Allow the device to charge for at least four hours to ensure optimal battery performance. While charging‚ you can browse the included files on the device. Once charged‚ power on the Sansa Clip by pressing and holding the power button. Follow the on-screen prompts to set your preferred language and date/time. You are now ready to begin transferring music and customizing your listening experience!

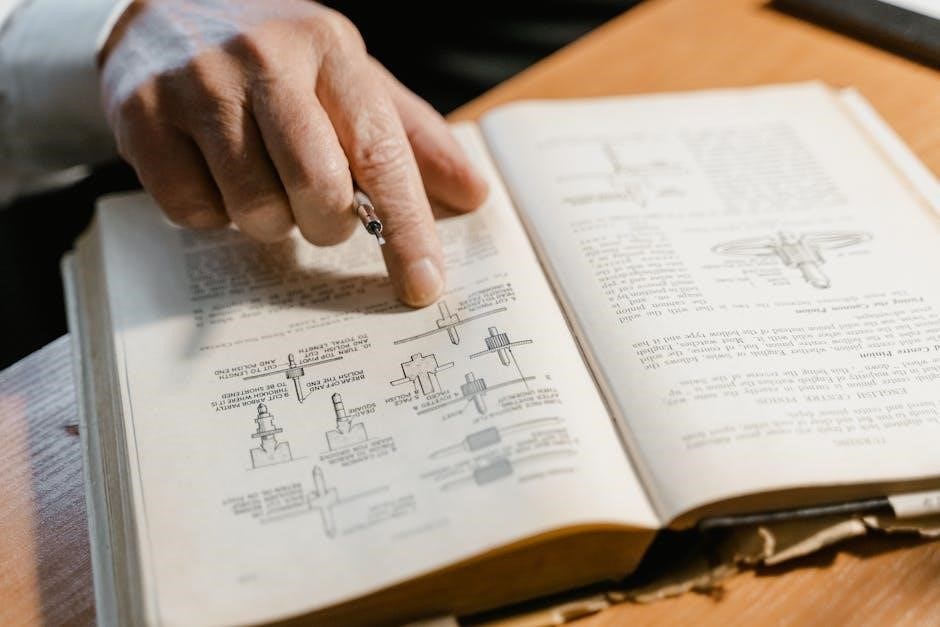

Device Overview: Buttons and Ports

The SanDisk Sansa Clip features a minimalist design with intuitive controls. On the front of the device‚ you’ll find the Navigation Pad – a four-way directional button used for menu navigation and selection. A central Select/Play/Pause button confirms choices and controls playback. Dedicated Volume Up/Down buttons allow for quick audio adjustments.

Located on the top edge is the Power/Lock button‚ used to turn the device on/off and lock the screen. The side of the player houses a Micro-USB port‚ serving as both the charging port and the data transfer interface. A small headphone jack (3.5mm) is also present for connecting your favorite headphones or earbuds. Finally‚ the integrated belt clip on the back ensures secure and convenient portability during workouts or commutes.

Powering On/Off and Basic Navigation

To power on your SanDisk Sansa Clip‚ press and hold the Power/Lock button located on the top of the device until the screen illuminates. To power off‚ repeat this process. A short press of the Power/Lock button will lock/unlock the screen‚ conserving battery life.

Basic navigation is managed using the Navigation Pad. Press up‚ down‚ left‚ or right to move through menus and lists. Press the Select/Play/Pause button to confirm your selection or start/pause music playback. Use the Volume Up/Down buttons to adjust the audio level. The Sansa Clip’s interface is designed for simplicity‚ allowing easy access to your music library‚ playlists‚ and settings. Familiarize yourself with these controls for a seamless user experience.

Transferring Music to Your Sansa Clip

Connecting to your computer is the first step. Use the included USB cable to connect the Sansa Clip to a USB port on your PC or Mac. The device will appear as a removable drive. You can then simply drag and drop music files directly onto the Sansa Clip’s drive.

Supported file formats are crucial; ensure your music is compatible (see the ‘Supported Audio Formats’ section). For optimal organization‚ create folders on the device to categorize your music. Regularly eject the device safely from your computer before disconnecting the USB cable to prevent data corruption. This straightforward process allows you to quickly populate your Sansa Clip with your favorite tunes.

Using Windows Media Player

Windows Media Player offers a streamlined method for syncing music. Connect your Sansa Clip to your computer via USB. Launch Windows Media Player and ensure your device is recognized. Drag and drop music files into your Windows Media Player library. Then‚ synchronize your library with the Sansa Clip by selecting the device and choosing the ‘Sync’ option.

Synchronization options allow you to choose specific playlists or your entire library. Windows Media Player automatically converts incompatible files‚ though quality may be affected. Regularly updating Windows Media Player ensures compatibility and optimal performance. This method provides a user-friendly interface for managing and transferring your music collection to your Sansa Clip.

Using iTunes (with SanDisk Media Converter)

iTunes compatibility requires the SanDisk Media Converter‚ as the Sansa Clip doesn’t directly support all iTunes file formats. Download and install the converter from the SanDisk website. Launch iTunes and connect your Sansa Clip via USB. The converter will appear as a device within iTunes. Select your desired music and initiate the conversion process through the SanDisk Media Converter interface.

Conversion settings allow you to choose output quality and format. Ensure compatibility by selecting supported formats like MP3. Synchronization then occurs automatically; This method allows iTunes users to enjoy their libraries on the Sansa Clip‚ despite inherent format limitations. Regularly check for converter updates for optimal performance and compatibility.

Supported Audio Formats

The SanDisk Sansa Clip offers broad audio format support‚ enhancing its versatility. MP3 is natively supported‚ ensuring widespread compatibility with most music libraries. WMA (Windows Media Audio) files are also directly playable‚ catering to Windows users. Additionally‚ the device supports AAC (Advanced Audio Coding)‚ a popular format known for its efficient compression and good audio quality.

For users with diverse audio collections‚ the Sansa Clip accommodates FLAC (Free Lossless Audio Codec) files‚ preserving original audio fidelity. However‚ utilizing the SanDisk Media Converter might be necessary for certain protected iTunes files or less common formats. Checking the official SanDisk documentation for the most up-to-date list is always recommended.

Creating and Managing Playlists

Playlists allow personalized listening experiences on your Sansa Clip. You can create them directly on the device‚ though managing them via computer software is often more efficient. Using Windows Media Player or iTunes (with the SanDisk Media Converter) provides a user-friendly interface for playlist creation. Simply drag and drop desired songs into a new playlist within the software.

Once created‚ synchronize the playlists to your Sansa Clip. The device supports a substantial number of playlists‚ accommodating diverse musical moods and activities. You can also edit existing playlists – adding‚ removing‚ or reordering tracks – through the computer software. Remember to always sync after making changes to ensure consistency between your library and the player.

Navigating Playlists on the Device

Accessing playlists on your Sansa Clip is straightforward. From the main menu‚ select the “Playlists” option using the directional buttons. A list of all synchronized playlists will appear on the screen. Use the up and down buttons to highlight the desired playlist‚ then press the select/center button to open it.

Within a playlist‚ you can navigate songs using the same directional buttons. Press select to begin playback. Options like shuffle and repeat are accessible during playback via the on-screen menu. The Sansa Clip’s interface is designed for ease of use‚ even while on the go. Quickly jump to different songs or playlists with minimal effort‚ ensuring uninterrupted enjoyment of your music collection;

Equalizer Settings and Sound Customization

Personalize your audio experience with the Sansa Clip’s built-in equalizer; Access the equalizer settings through the main menu‚ typically found under “Sound” or “Playback” options. You’ll find several preset equalizer modes‚ such as Rock‚ Pop‚ Classical‚ and Jazz‚ designed to enhance specific music genres.

For more granular control‚ select the “Custom” mode. This allows you to manually adjust the levels for different frequency bands‚ tailoring the sound to your precise preferences. Experiment with these settings to achieve optimal sound quality based on your headphones and musical tastes. Remember to save your custom settings for future use. The Sansa Clip empowers you to fine-tune your listening experience.

FM Radio Functionality

Enjoy free over-the-air radio with the Sansa Clip’s integrated FM radio receiver. To access the FM radio‚ navigate to the “Radio” option in the main menu. The first time you use the radio‚ you’ll need to perform a scan to find available stations. The device automatically saves discovered stations for quick access.

Use the directional pad to navigate through the station list. You can also manually tune to specific frequencies if desired. The Sansa Clip supports FM radio recording‚ allowing you to capture your favorite shows or songs for later listening. Note that recording quality depends on the signal strength. Ensure headphones are connected to act as the antenna for optimal reception.

Firmware Updates and Troubleshooting

Keep your Sansa Clip performing optimally by checking for firmware updates regularly. SanDisk occasionally releases updates to improve performance‚ fix bugs‚ and add new features. Visit the SanDisk website to download the latest firmware and instructions for installation – typically involving connecting the device to a computer via USB.

Troubleshooting common issues: If your device freezes‚ try a simple reset by holding the power button for several seconds. For unresponsive screens‚ ensure the device is adequately charged. If music transfer fails‚ verify USB connection and file compatibility. If the radio doesn’t scan‚ ensure headphones are connected. Refer to the SanDisk support website for more detailed troubleshooting guides and FAQs.

Common Issues and Solutions

Experiencing problems with your Sansa Clip? A frequent issue is the device not recognizing files – ensure they are in a supported format (MP3‚ WMA‚ etc.). If the screen freezes‚ a forced restart (holding the power button) often resolves it. Low volume can be addressed by checking volume settings on both the device and connected headphones.

USB connectivity problems are common; try a different USB port or cable. Radio reception issues may stem from weak signal strength or disconnected headphones (acting as an antenna). If the battery drains quickly‚ reduce screen brightness and disable unnecessary features. For persistent problems‚ consult the SanDisk support website for detailed troubleshooting steps and potential firmware updates that address known bugs.

Battery Life and Charging

Maximizing your Sansa Clip’s playtime requires understanding its battery characteristics. Expect approximately 15-20 hours of audio playback on a full charge‚ though this varies with volume level‚ screen brightness‚ and feature usage (like the FM radio). Charging is simple: connect the device to a computer via the included USB cable.

A full charge typically takes around 3-4 hours. Avoid using the device while charging‚ as this can prolong the charging time. To prolong battery life‚ reduce screen timeout‚ lower the volume‚ and disable features when not in use. Avoid exposing the device to extreme temperatures‚ which can degrade battery performance. Only use the provided USB cable or a certified replacement.

Belt Clip and Physical Maintenance

The integrated belt clip on your Sansa Clip allows for convenient‚ hands-free portability during workouts or daily activities. Ensure the clip is securely fastened to your clothing to prevent accidental drops. For cleaning‚ use a soft‚ dry cloth to wipe the device’s exterior. Avoid harsh chemicals or abrasive cleaners‚ as these can damage the finish.

Do not submerge the device in water or expose it to excessive moisture. While designed to be durable‚ the Sansa Clip is not waterproof. Regularly inspect the USB port for debris and gently remove any obstructions with a non-metallic tool. Store the device in a cool‚ dry place when not in use to protect it from environmental factors. Handle with care to avoid scratches or impacts.

Advanced Features: Voice Recording

The Sansa Clip boasts a built-in voice recording feature‚ allowing you to capture notes‚ lectures‚ or personal memos. Access this function through the device’s menu system; navigate to the ‘Voice Recorder’ option. Recording quality depends on the surrounding environment and proximity to the microphone. Ensure a quiet space for optimal clarity.

Recordings are saved as WAV files within the ‘Recordings’ folder on your Sansa Clip. You can then transfer these files to your computer via USB connection for archiving or editing. Playback is simple – select a recording from the folder and press play. The device offers basic playback controls like pause‚ fast forward‚ and rewind. Remember to manage storage space‚ as recordings consume memory.

SanDisk Media Converter Details

The SanDisk Media Converter is crucial for converting audio files incompatible with the Sansa Clip. Specifically‚ it’s essential for iTunes users‚ as the device doesn’t natively support AAC files. This free software transforms protected or unprotected WMA or AAC files into the supported MP3 format.

Download and install the converter from the SanDisk website. The process is straightforward‚ guiding you through each step. Import your music into the converter‚ select your desired output quality (bitrate)‚ and initiate the conversion. The converted MP3 files can then be easily transferred to your Sansa Clip via USB. Remember to check the converted files on your computer before transferring to ensure proper functionality. It’s a vital tool for expanding your music library’s compatibility.

Safety Precautions and Warranty Information

To ensure safe operation of your SanDisk Sansa Clip‚ avoid exposing it to extreme temperatures‚ humidity‚ or direct sunlight. Do not disassemble the device‚ as this will void the warranty and may cause damage. Handle with care to prevent physical shock or water damage. Use only the provided USB cable for charging and data transfer.

The SanDisk Sansa Clip typically comes with a limited warranty‚ usually covering defects in materials and workmanship for a specified period – often one year from the date of purchase. Retain your proof of purchase for warranty claims. Warranty does not cover damage caused by misuse‚ accidents‚ or unauthorized modifications. Refer to the official SanDisk website for complete warranty details and claim procedures.