The 7.3 Powerstroke engine, known for its reliability and performance, often requires a detailed wiring diagram for modifications and repairs. This guide provides essential insights into its electrical system.

Overview of the 7.3L Engine

The 7.3L Powerstroke engine, a diesel V8, is renowned for its reliability and durability. Produced from 1994 to 2003, it powered Ford trucks, delivering exceptional torque and horsepower; Its direct-injection fuel system and cast-iron construction made it a favorite for heavy-duty applications. This engine’s robust design and performance capabilities have made it a popular choice for both work and performance upgrades, supported by detailed wiring diagrams for modifications and repairs.

Importance of Wiring Diagrams for Maintenance and Modifications

The 7.3L Powerstroke engine, produced from 1994 to 2003, relies heavily on accurate wiring diagrams for troubleshooting and modifications. These diagrams provide a detailed map of the electrical system, ensuring proper diagnosis of faults and safe installation of upgrades like gauges or performance chips. They are essential for maintaining electrical integrity and preventing damage during repairs or customizations.

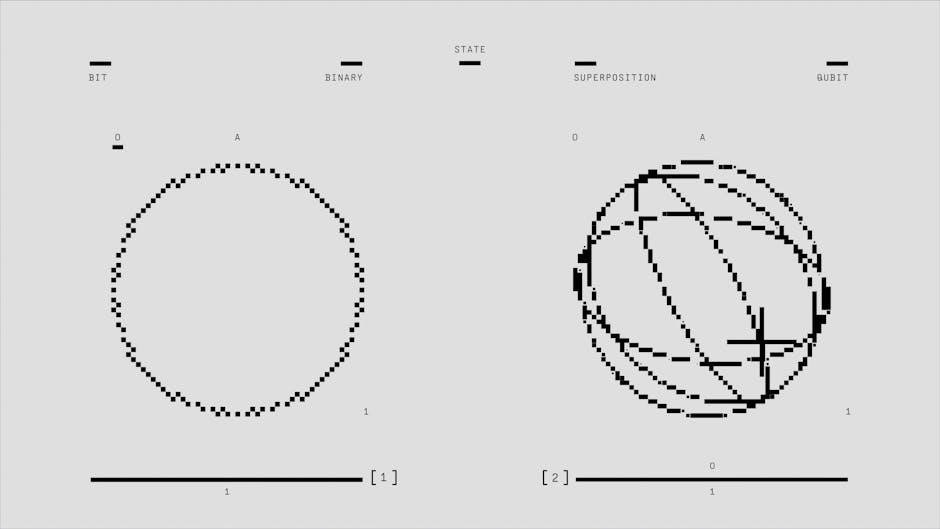

Understanding the Wiring Diagram

The wiring diagram is a visual blueprint of the electrical system, detailing connections, components, and circuits. It helps identify wires, symbols, and their functions, enabling precise diagnostics and modifications.

Components of the Wiring Diagram

The wiring diagram includes detailed sections for the battery, starter motor, alternator, fuel injectors, and PCM. It outlines circuit paths, connectors, and harnesses, ensuring clarity for troubleshooting and upgrades. Color coding and symbols specify wire functions, aiding technicians in precise diagnostics and modifications.

Symbols and Layout

The wiring diagram uses standardized symbols and a structured layout to represent components and connections. Circles denote connections, while rectangles represent components like relays and fuses. Wires are shown as lines, with colors indicating specific functions. The layout is organized into sections, simplifying circuit tracing and wire identification for technicians and enthusiasts alike.

Locating the Wiring Diagram

Wiring diagrams for the 7.3 Powerstroke can be found in official Ford manuals, online forums, or reliable PDF downloads, ensuring accurate information for repairs and modifications.

Official Ford Manuals and Resources

Official Ford manuals provide comprehensive wiring diagrams for the 7.3 Powerstroke engine. These resources are available through Ford’s official website, authorized dealerships, or repair manuals. They include detailed schematics, component locations, and circuit descriptions, ensuring accurate information for diagnostics and repairs. Additionally, Ford’s technical service bulletins often contain updated wiring information for specific issues.

Online Forums and Communities

Online forums and communities, such as Ford F-250/F-350 6.7L forums, offer extensive resources for 7.3 Powerstroke wiring diagrams. Members often share PDF files, repair guides, and troubleshooting tips. These platforms provide valuable insights from experienced technicians and enthusiasts, making them a reliable source for DIY modifications and repairs. They also include discussions on common electrical issues and solutions.

PDF Downloads and Reliable Sources

Reliable sources for 7.3 Powerstroke wiring diagrams include official Ford service manuals and trusted automotive forums. Websites like Ford F-250/F-350 6.7L forums often provide downloadable PDFs with detailed schematics. Specialty auto repair websites also offer wiring diagrams tailored for specific years and modifications. These resources ensure accurate and safe electrical system repairs and upgrades for your 7.3L engine.

Key Components of the 7.3 Powerstroke Wiring System

The wiring system includes the Powertrain Control Module (PCM), Fuel Injector Control Module (FICM), and Idle Air Control (IAC) motor. These components ensure proper engine operation and communication.

Powertrain Control Module (PCM)

The PCM is the brain of the 7.3 Powerstroke engine, managing functions like fuel injection, timing, and emissions. It processes data from sensors to optimize performance and efficiency. Referencing the wiring diagram helps technicians diagnose PCM-related issues, such as faulty connections or sensor malfunctions, ensuring accurate repairs and maintaining engine reliability.

Idle Air Control (IAC) Motor

The IAC motor regulates engine idle speed by adjusting airflow; A wiring diagram helps identify connections to sensors and the PCM. Proper installation ensures smooth idling, while faults can cause rough engine operation. Technicians use diagrams to diagnose issues like stuck motors or faulty circuits, essential for maintaining optimal engine performance and idle control.

Fuel Injector Control Module (FICM)

The FICM manages fuel injector operation, ensuring precise fuel delivery. A wiring diagram is crucial for diagnosing FICM-related issues, such as power supply problems or communication faults. Technicians use diagrams to trace circuits, identify faulty connections, and perform repairs, maintaining optimal engine performance and fuel efficiency.

Common Modifications and Upgrades

Popular upgrades for the 7.3 Powerstroke include installing aftermarket gauges, performance chips, and auxiliary lighting. These modifications often require a wiring diagram to ensure proper installation and functionality.

Installation of Aftermarket Gauges

Installing aftermarket gauges on a 7.3 Powerstroke requires precise wiring diagram references to ensure correct connections. Gauges monitor vital engine parameters like boost pressure and exhaust temperature, enhancing performance tracking. Proper installation involves identifying the right wires for power, ground, and signal sources. A wiring diagram helps avoid electrical system damage and ensures accurate readings.

Upgrading to Performance Chips

Upgrading to performance chips enhances engine performance by modifying fuel injection and timing. A wiring diagram is essential to safely install these chips, ensuring proper connections to the PCM and fuel system. Modifications like adjusting the Idle Air Control (IAC) motor wiring can improve idle stability. Always refer to the diagram to avoid electrical system damage and optimize engine efficiency.

Adding Auxiliary Lighting and Accessories

Installing auxiliary lighting and accessories requires a detailed wiring diagram to identify power sources and ensure proper connections. The diagram helps locate the correct wires for components like fog lights or aftermarket gauges. Always consult the wiring diagram to avoid short circuits and ensure compatibility with the vehicle’s electrical system, particularly the FICM and PCM connections.

Troubleshooting Common Electrical Issues

Use the wiring diagram to identify blown fuses, faulty connections, or malfunctioning components. Common issues include incorrect wire routing and damaged sensors, which can disrupt engine performance.

Diagnosing Faults Using the Wiring Diagram

The wiring diagram is essential for identifying electrical issues in the 7.3 Powerstroke engine. By tracing circuits and comparing them to the diagram, technicians can locate blown fuses, faulty sensors, or malfunctioning components. This method ensures accurate diagnostics, preventing unnecessary repairs and saving time. Common issues include faulty connections or incorrect wire routing.

Common Issues and Solutions

Common issues with the 7.3 Powerstroke wiring system include blown fuses, faulty sensors, and corroded connections. Solutions involve replacing damaged components, cleaning connections, and ensuring proper wire routing. For example, a malfunctioning IAC motor may require a 13k ohm resistor installation. Always refer to the wiring diagram for precise troubleshooting and repairs to maintain optimal engine performance.

Safety Precautions When Working with Wiring

Always disconnect the battery and ensure the engine is off before working with wiring. Use insulated tools to prevent electrical shocks and avoid live circuits for safety.

Best Practices for Electrical Work

Always consult the wiring diagram before starting work. Use proper tools and test wires with a multimeter to avoid damage. Ensure all connections are secure and insulated. Avoid shortcuts or improvised repairs, as they can lead to system malfunctions. Follow manufacturer guidelines for wiring repairs to maintain reliability and safety throughout the process.

Protecting the Vehicle and Technician

Disconnect the battery before starting work to prevent electrical shocks. Use insulated tools to avoid short circuits. Ground the vehicle to prevent static discharge. Wear protective gear like gloves and goggles. Ensure proper ventilation when working with electrical systems. Regularly inspect wiring and connections to prevent damage. Follow safety guidelines to protect both the technician and the vehicle during repairs.

Tools and Materials Needed for Wiring Repairs

Essential tools include a multimeter, wiring diagram, circuit testers, and soldering kit. Materials like high-quality wires, connectors, and heat shrink tubing are necessary for reliable repairs.

Essential Tools for the Job

Key tools include a multimeter for voltage testing, wire strippers for preparing wires, a soldering iron for secure connections, and a wiring diagram for guidance. Additionally, circuit testers, connectors, heat shrink tubing, needle-nose pliers, voltage drop testers, screwdrivers, and a LED light ensure efficient and safe wiring repairs.

Recommended Materials and Kits

High-quality wiring harnesses, heat-resistant connectors, and heat shrink tubing are essential. Use circuit protection components like fuses and relays. Invest in a wiring repair kit with crimpers and terminals. For reliability, opt for Ford OEM or trusted aftermarket parts. Ensure all materials meet automotive standards to withstand harsh conditions and maintain optimal performance.

Step-by-Step Guide to Reading the Wiring Diagram

Start by identifying components and decoding symbols. Trace circuits to understand connections. Use this guide to troubleshoot or install new parts effectively.

Interpreting the Diagram

Start by understanding the layout and symbols. Color-coded wires indicate specific functions. Trace circuits from the PCM to components like the IAC motor. Identify grounds and power sources. Use the legend for symbol meanings. This systematic approach ensures accurate repairs and modifications to your 7.3 Powerstroke engine’s electrical system.

Tracing Circuits and Identifying Wires

Begin by locating the Powertrain Control Module (PCM) and Fuel Injector Control Module (FICM) on the diagram. Trace circuits using color-coded wires and symbols. Identify ground wires (typically black) and power sources (red or yellow). Use the diagram to pinpoint connectors and components. For example, the green wire and white with brown tracer are key for idle adjustment.

Mastering the 7.3 Powerstroke wiring diagram enhances maintenance and modifications. For further learning, explore official Ford manuals, online forums, and reliable PDF downloads for detailed guidance and troubleshooting.

The 7.3 Powerstroke engine is renowned for its durability and performance. Wiring diagrams are crucial for troubleshooting, modifications, and understanding electrical systems. Key components include the PCM, FICM, and IAC motor. Reliable sources like official Ford manuals, online forums, and PDF downloads provide essential guidance for DIY enthusiasts and technicians alike.

Recommended Reading and Online Communities

For comprehensive guides, refer to official Ford manuals and forums like Ford Truck Enthusiasts. Online communities such as Diesel Forum and specialized PDF downloads offer detailed wiring diagrams and troubleshooting tips. These resources are invaluable for both beginners and experienced technicians working with the 7.3 Powerstroke engine.